For Melissa Hook — who works at our Eureka Innovation Lab as a finishing technician and the Environmental, Health and Safety (EHS) coordinator — sustainability isn’t just part of her work, it’s a personal passion.

So when she wanted to learn more about how we approach sustainability at Levi Srauss & Co., Bart Sights, vice president of Technical Innovation for LS&Co., and Michael Kobori, vice president of sustainability, LS&Co., came up with the perfect solution: an “internship” with our Sustainability team. For two months this summer, Melissa went beyond the four walls of the lab at Eureka to ground herself in how we approach sustainability across the company.

We sat down with Melissa to talk to her about her experience and the unique opportunity she was given.

What inspired you to want to learn more about sustainability?

My mother taught me to sew when I was 6 years old, while doing historical re-enactments for the gold rush era at Sutter’s Fort in Sacramento. When a dress was too small for me, we would take out the waist or add length to the hem. I understood what sustainable apparel meant on a personal level.

Once I learned about the environmental and social impacts of the apparel industry in college, my passion evolved to wanting to make the apparel industry more sustainable.

Why do you think sustainability is so important at LS&Co.?

The apparel industry employs more people around the world than any other industry, and 80 percent of those workers are women.

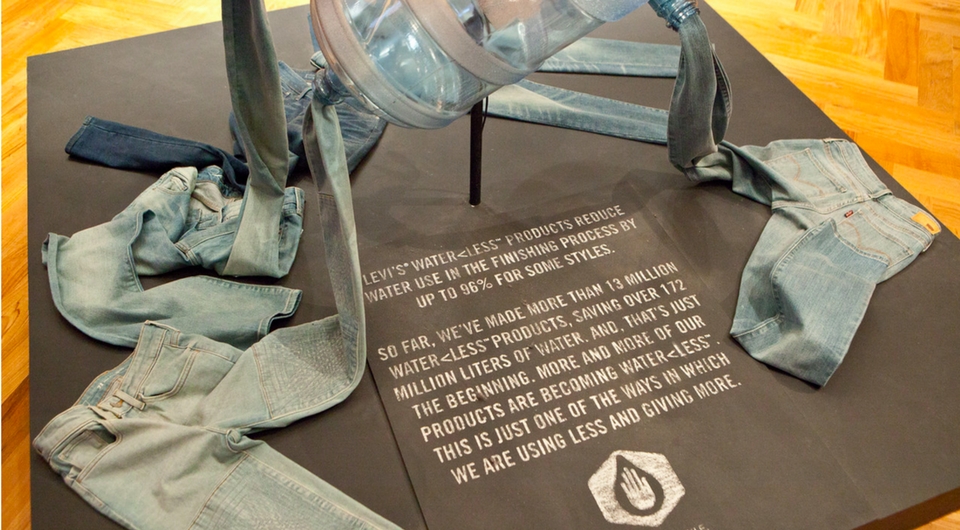

LS&Co. is a global company, which means we impact thousands of people’s lives, and by introducing sustainability initiatives like Worker Well-being and Water<Less™, we can push the needle farther than smaller organizations.

While training for Project Wet I learned it takes 1,000 gallons of water to make a pair of Levi’s® jeans, and 68 percent of that is used in the cotton-growing phase. With rising temperatures around the world, cotton may need even more water in the future. If we want to be in business for another 100 years, we need to conserve this precious resource that our business relies on so heavily.

What is the relationship between sustainability and innovation at LS&Co.?

In order to be sustainable, we must innovate. The Eureka Lab was built to foster innovation and answer questions like: How do we use less water in our finishing processes, or can we use an alternative to perfluorinated chemicals (PFCs) for waterproofing our Commuter™ wear? Sustainable innovation is all about interrupting the status quo, finding leverage points and fostering change to use fewer resources and better the lives of our workers.

What was the most rewarding aspect of the internship?

The most rewarding aspect of the summer was getting the opportunity to step out of my Eureka bubble and share my ideas for LS&Co.’s future in sustainability with the passionate and intelligent members of the Sustainability team. Each team member has his or her own specialization, whether it be closed-loop strategies, water systems engineering or business acumen. To have the opportunity to work with each of them in a different capacity each day was both humbling and enlightening.

How do you think learning more about sustainability will enhance your regular day job?

Learning more about how our sustainability initiatives are strategized helps me think past our one-garment-at-a-time perspective at Eureka. That one garment we are creating, and its recipe, are going to be copied thousands of times, affecting not only the people who will wear the garments but also the seamstresses and finishers who are producing them. As the Environmental, Health and Safety Coordinator and a Finishing Technician, how can I improve our standard operating procedures and have conversations with our finishing managers to improve the processes we make on repeat every day? These are the questions I now ponder.